Reciprocating Friction Tester distribution|linear friction tribometer test : suppliers The rig used is a slightly modified version of the one developed for unidirectional sliding by the present authors in Bin Jaber et al. [36].The approach is somewhat similar to the sled-type friction test in ASTM D1894 [37].A schematic representation of the rig is shown in Fig. 2 (with numbers indicating the key components). The contact adopted for the study was a flat . As apostas ocorrem semanalmente, podendo ser realizadas diariamente. Os pagamentos são feitos no prazo máximo da segunda-feira subsequente à aposta, podendo, em caráter de exceção, serem efetuados previamente à data mencionada. A equipe Aposta Certa, filiada à pai.bet, presta atendimento personalizado e individual via WhatsApp a seus .

{plog:ftitle_list}

Resultado da Acesse os serviços online da Prefeitura de Guaíra, como autoatendimento, bolsa família, habitação, IPTU, nota fiscal e mais. Veja também as .

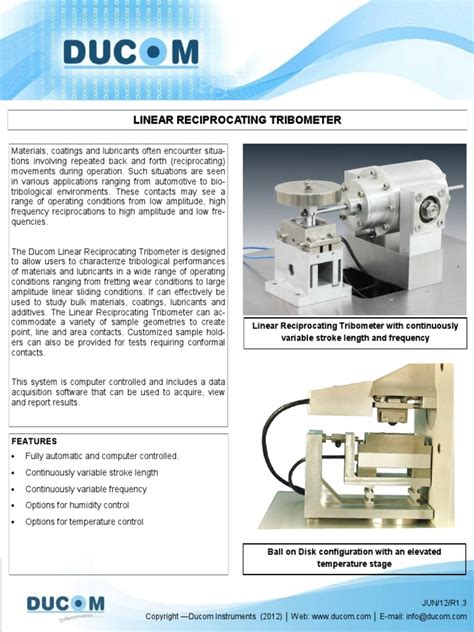

The aim of this work is thus to develop a novel reciprocating tribometer and test method that enables friction and wear tests under low-speed reciprocatory sliding with contact pressures up to 90 MPa in a flat-on-flat contact configuration.Evaluate fuel lubricity, predict the performance of additives, and study friction wear with our HFRR high frequency reciprocating rig. This next generation Rtec Instruments HFRR testing machine contains programmable force control (no . Abstract The microstructure of the materials constituting a metallic frictional contact strongly influences tribological performance. Being able to tailor friction and wear is challenging due to the complex microstructure evolution .Using various sensors it measures friction, wear, and adhesion of any reciprocating test setup with ease. The patented in-line 3D profilometer automatically measures topography change during the test. The module .

The rig used is a slightly modified version of the one developed for unidirectional sliding by the present authors in Bin Jaber et al. [36].The approach is somewhat similar to the sled-type friction test in ASTM D1894 [37].A schematic representation of the rig is shown in Fig. 2 (with numbers indicating the key components). The contact adopted for the study was a flat . In the present work, effects of significant factors on friction coefficient and friction force are analyzed on reciprocating friction and wear test rig (RFWTR) by using Taguchi approach. The Taguchi method (TM) is employed for evaluate the experimental work, analyzed the effect of working parameters for the PRA and decides the influence of . A reciprocating friction and wear tester based on Lab VIEW was designed and built to preliminarily test the friction and wear characteristics of different materials under different test conditions and lubricant additives. The mechanical structure and measurement, and control system were optimized. It carried out functional test studies. The test shows that the test . At the initial stages of friction, the presence of interfaces notably hindered the transfer of temperature, defects, and atomic displacements in the workpiece, and this inhibitory effect weakened with an increasing number of friction cycles. The TCP phases experienced stratification due to the overall deformation they underwent.

Friction tests were carried out, without lubrication and under ambient conditions, on a reciprocating friction tester in which a ball-on-flat con-tact configuration was adopted.The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of .For friction coefficient and wear rate measurement, the High Temperature Tribometer provides an ideal test setup for simulating contact between two materials at their operating temperature. . “Modelization” software for simulating Hertzian elastic contact stress and strain distribution; User-defined friction threshold auto-protection . 2.3. Friction Samples and Test Method. In the reciprocating friction test, the upper specimen was fresh rape stalk obtained during harvest and fixed at the bottom curved surface of the special fixture. Each rape stalk was cut into a rectangular shape (length 50 mm, width 10 mm) and a V-shape cut was made at each end (Figures 5(a) and 5(b)).

(a) Horizontal beam chassis with a slot in the center for the specimen to pass through, mounted on 2 vertical beam-columns placed on either side between the actuator and the load frame column. (b) Free body diagram of the specimen and pad in the following cases: (i) fretting test; (ii) reciprocating sliding friction test.Comparative study on sliding friction and wear properties of low alloy wear-resistant steel Hardox400 and NM400 at room temperature using Retc multi-function friction and wear tester.

The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of engine oils, greases and other . The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece. The acquisition of anolog signals is done . 2.1 Pin-on-Disk Tribometer. The most commonly used configuration for testing materials is the pin-on-disk method in either rotating or linear-reciprocating modes. The corresponding ASTM standards, G99 [] and G133 [], include the measurement of friction coefficient as well as wear rate of the sample and the static partner.The pin-on-disk setup has . Piston ring sealing is of great importance in oil-free reciprocating compressors for high pressure application. Pressure distribution and frictional heat on piston rings have been investigated .

Typical experimental results obtained with the computer-aided friction tester are presented for a thermoplastic sample rubbed against a steel slider with a polished surface in dry conditions. . Design of reciprocating friction and wear testing machine and its computer control system . Load distribution and hysteretic losses. Mechanism and .Keywords: compressor, friction, valve design, minimum oil film thickness, pressure distribution, parametric study 1. INTRODUCTION Reciprocating compressors technology is mature but still has high friction losses. Measuring friction loss and friction forces is extremely complicated yet highly important for design of compressor. Measurement and control system design and texture anti-friction test of reciprocating friction tester based on compliant mechanism November 2021 DOI: 10.1117/12.2612004

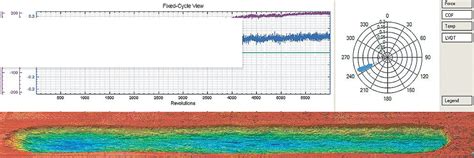

Results of the 5000 cycles linear reciprocating test. a) Plots of the coefficient of friction (CoF) vs. cycles for the AlCrN and AlCrVN coatings. b), c) Optical images of the Al 2 O 3 ball against AlCrN and AlCrVN. d), e) Optical profile of the wear track, including the depth profiles taken in different zones. Blue color corresponds to the . Wide discrepancies in the chosen parameters make model tests complex and difficult to compare. There are investigations that compare reciprocating and rotating test methods with different results depending on the test method [9], [10].The common understanding is that test parameters should be as close as possible to the real contact situation in the engine.Friction force range: up to 20 N (5 N option) Friction force resolution: 0.06 mN (0.015 mN option) Rotating movement: Speed: 0.2 rpm to 2000 rpm (600 rpm option) Radius: up to 40 mm: Maximum torque: 450 mN.m: Linear reciprocating movement 1) Stroke length: up to 60 mm: Speed: up to 370 mm/s: Frequency: 0.01 Hz to 10 Hz: Rotational reciprocating .

A reciprocating friction and wear tester based on Lab VIEW was designed and built to preliminarily test the friction and wear characteristics of different materials under different test conditions . The aim of the present work was to investigate the reciprocating friction and wear behavior of MCMBs-derived reaction-formed SiC submitted to dry sliding tests against bearing steel ball under different loads, in order to determine the effects that the microstructural features and properties can have on friction and wear behavior, as well as to . A simulation of a reciprocating sliding test was carried out on the ABAQUS/Explicit software. The numerical model consists of a rough parallelepiped aluminum sample of 2 × 2 × 1 mm 3 in dimension and a rigid ball with a radius R = 5 mm (Fig. 1).The simulation starts with the application of a normal load F n = 1 N on the rigid ball. . Then, the . The vertical load, friction ball diameter and reciprocating movement frequency (friction speed) are selected as the experiment factors. The cutting tools was installed in the special designed fixture on a reciprocating movement wear test machine. The wear depth increases with the increase in the Z-load, ball diameter and frequency.

bottle waters ph test pirtures

The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece.

reciprocating tribometer pdf

linear wear friction testing

linear friction tribometer test

Conheça o Catálogo Globoplay de originais, podcasts, filmes.

Reciprocating Friction Tester distribution|linear friction tribometer test